Some very happy memories this morning seeing this Gearcase in the TMS workshop!- a project which I was involved in back in 2007/8.

TMS offer full Gearbox inspections as part of our Turbine maintenance package, with OEM trained Gearbox Field Engineers embedded within our team we can provide inspections as part of the whole train outage or as a stand alone project.

Turbine Rebuild-SST400 Siemens Machine

Working towards commissioning of the Overhauled Rotor following a detailed inspection at our workshops. Our Customer is looking to us to help plan the next five years maintenance schedules in line with their financial commitments.

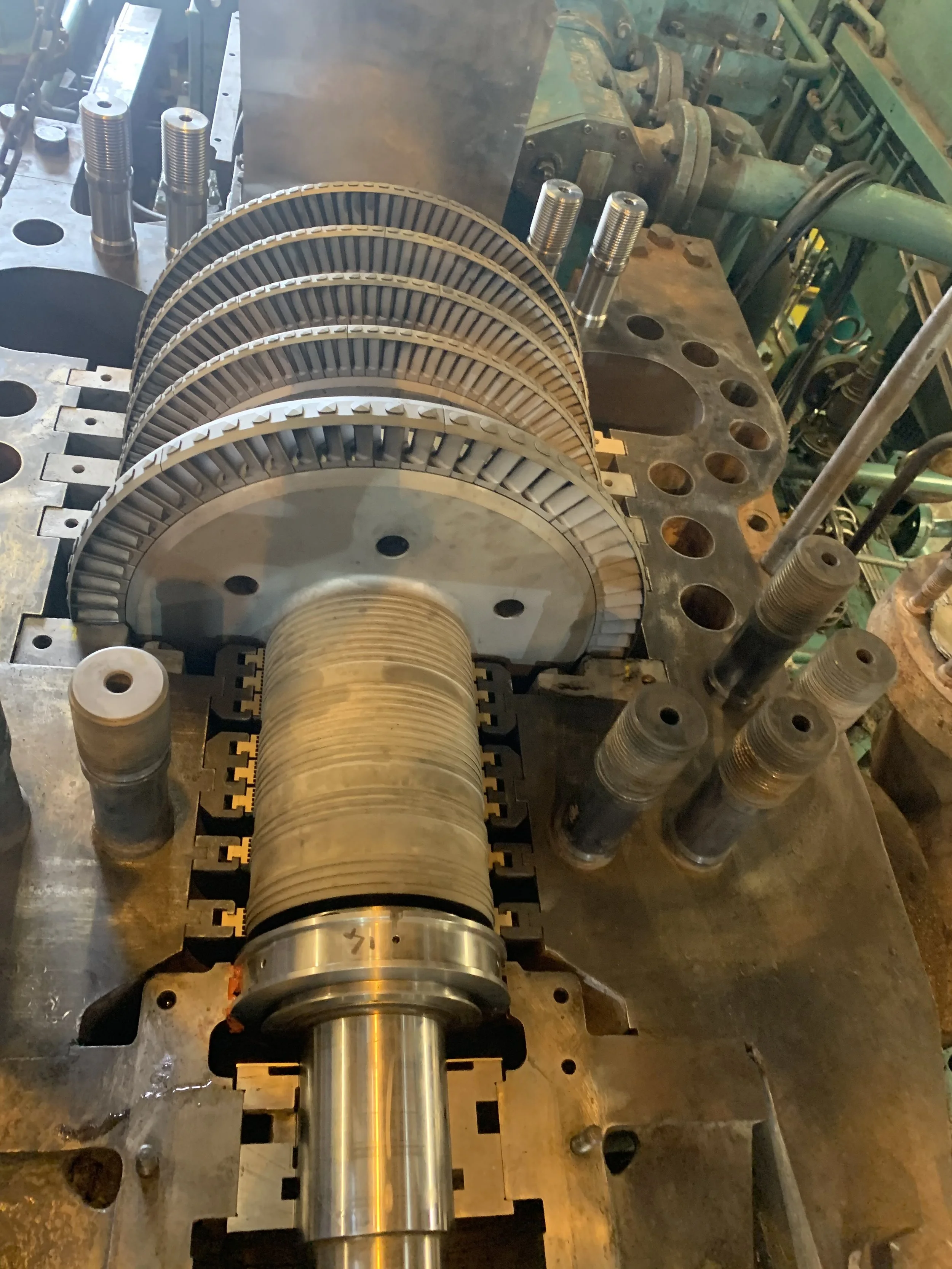

8Mwe Ansaldo Steam Turbine Major Service

Looking down on the turbine package following removal of the top casing for full inspection and overhaul. This is part of a major planned outage on an 8Mwe machine. TMS have worked with this Customer for many years and our knowledge and history of the installation ensure we meet the Clients own commercial commitments

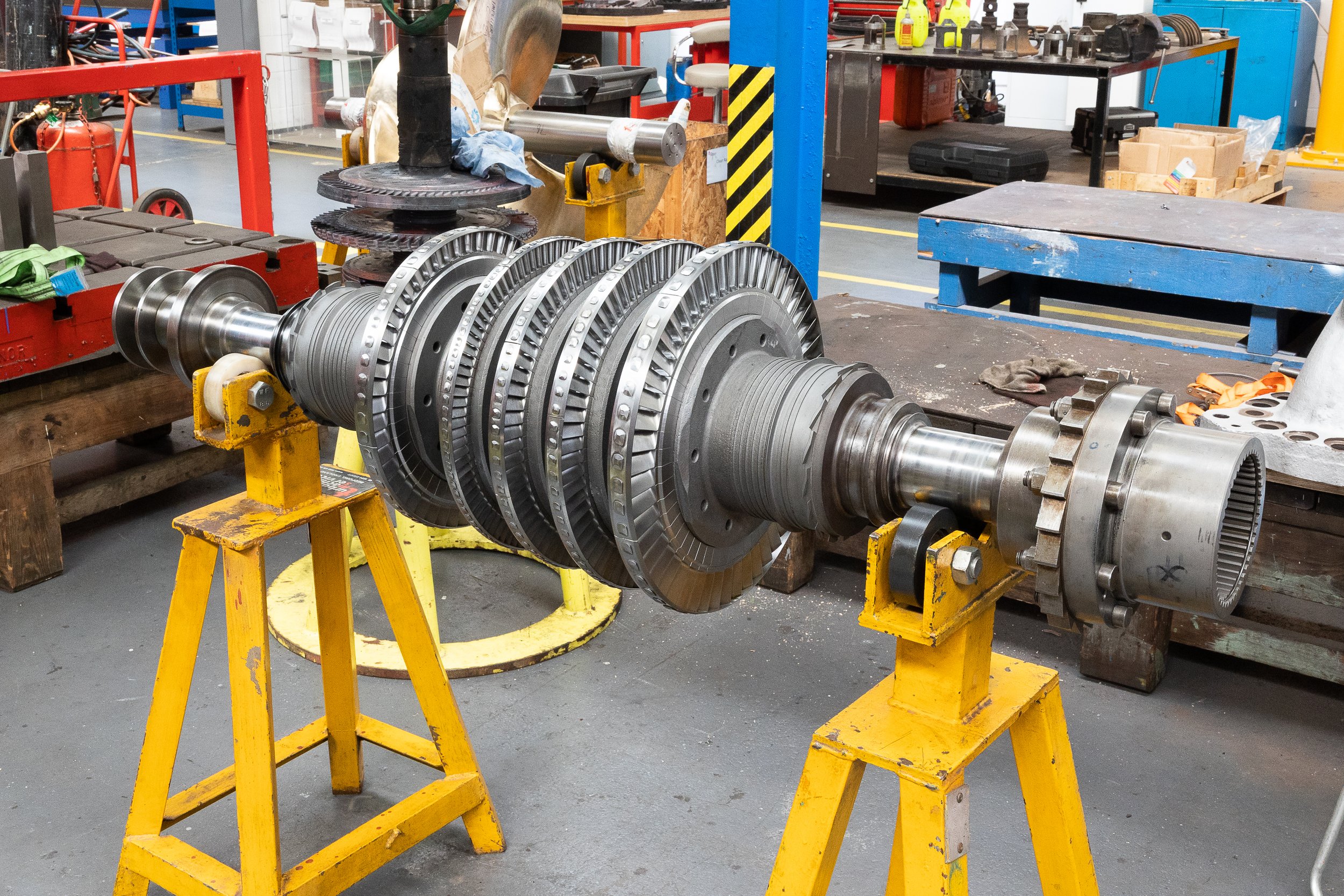

Worthington Simpson In-House Turbine overhaul

A recently overhauled Worthington Turbine ready to be returned to site for installation an commissioning. This internal inspection and repair project was just a small part of our Customers process outage, however it is a critical item and any issues and delays can cause both operational and financial implications to our Clients business.

The Turbine is now installed and operating to its full capacity.

SIemens Steam Turbine Package overhaul

Some photos from site this week, part way through a rejuvenation project for one of our Customers, removal of 24Mwe Turbine Rotor and Gearbox Internals for shipment back to the workshop for detailed inspection. We have been working with the end user for over 12 months now planning the various aspects of the project to meet their requirements for future Power Generation.

Gearbox Overhaul

As part of an ongoing Sitework and Workshop project ,We have twin input single, output gear set in for inspection. Our ability to manage the whole turbine package provides the Customer with confidence and the ability to keep all aspects of the contract under one roof!

This machine has input speeds of 11203 & 5602 RPM reducing to 1500 and with a rated power of 13.2Mwe

A photo of a recently re-bladed 5Mwe Turbine Rotor which required all five rows to be replaced. As part of the planning for any outage we look to cover any unexpected issues, and with this project we ensured that blade material was available with our trusted suppliers should we need to carry out any major reclamation work.

Looking ahead has enabled us to expedite the repair whilst keeping the Customer fully up to speed with the progress. We return to site next week to fit and commission the set.

Single Stage Turbine Overhauls

As part of a long term commitment to one of our Key Customers TMS offer fixed pricing for Strip, inspect and report of single stage turbines within our workshop facility, as we move through the summer months we enter into their Boiler TAR season and part of the scope is to overhaul their fan and pump drive turbines. The machines will receive a full overhaul and rebuild and will also be subject to an air test following rebuild to test the trip mechanism- units will then be painted to Customer specifications and returned to site.

ROLLS-ROYCE RB211 Compressor Drive Gearbox

Gas Turbine Driven Compressor Gear internals returned to the workshop for full inspection, crack detection & balancing ahead of a major outage later this year. These items will be ready and available should the existing gearbox show any signs of serious wear.

5MWe Turbine Rotor Inspection and repair

Rotor returned as part of a Major overhaul, Blade and Diaphragm repairs to be carried out along with High Speed Balancing.

Workshop Overhauls

Various components from different industries including Oil and Gas, Petrochemical & Power Generation installations.

Worthington Simpson Turbine Repair

Another single stage machine in for inspection and overhaul, stripped and apart within a shift. Recommendations are now being collated and will shortly be submitted to the client for discussion.

its imperative to respond quickly and efficiently to allow Customers to make informed decisions regarding their overhauled equipment.

Axial Compressor Major Outage

Axial Compressor rotor removal, part of a 14 day outage for a Customer who has very tight working parameters due to their own industry requirements.

Scope of work included Full Gearbox Overhaul, Coupling inspection and overhaul & Motor Inspection and Repair.

Customer Steam Turbine Package Awareness Training

Some great interaction with a long standing Customer who asked us to provide a Steam Turbine Package related training session at their Power Plant. The discussion covered all aspects of the train from Turbine through Gearbox and Generator and ended with an overview of the Controls and Monitoring system.

These gatherings are always a "2 way street" as we often learn more from the operators about some of the issues they face on site, which may not be specifically related to the Turbine package, but do have an outside influence on its running conditions.

We can provide generic or specific training on a wide range of subjects, either at site or our facility in Bedford which can be adapted to suit each individual clients needs.

if you feel this would benefit your business, feel free to make contact and we can begin discussions,

Parallel Shaft Gearbox Inspection

A recent Steam Turbine Package major overhaul included the full inspection of a 2.5Mwe Allen Gears Parallel shaft gearbox, the overhaul included bearing checks, replacement RTDS, Full NDT survey and tooth pattern studies, once completed all alignment checks were recorded and the machine was returned to service

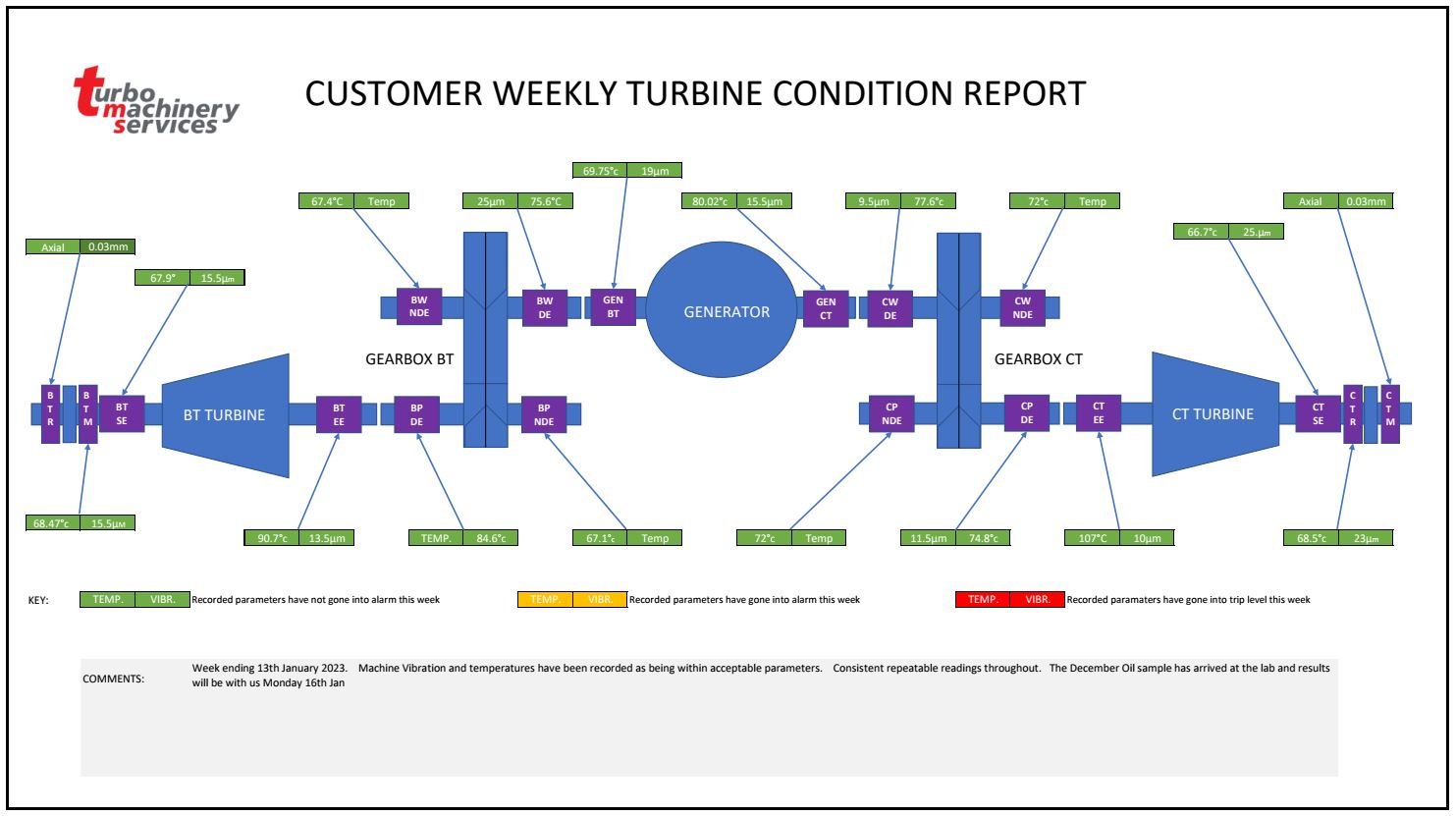

Turbine Remote Monitoring Support

It's nice on a Friday when we can provide our weekly turbine train health report to our customers and everything has been in the green. Testament to the complete LTSA package we provide. #LTSA #completecare

Fixing and Fastener Spare Parts

A selection of various fixings manufactured and ready to ship to the customer ahead of this years outage ensuring that all parts requirements are in the stores waiting!

Steam Turbine Major Overhaul

Photos of recent major overhaul, Originally installed early 1990's TMS have worked with our Client for many years now helping them support their own Customer with Steam and Power.

The benefits and positives of a long term relationship can never be underestimated, knowledge of the machine running history and plant conditions is invaluable.

Integrally Geared Rotor Inspection

1 of 2 Integrally geared compressor rotors returned for dimensional checks and balancing before installation in Q1 outage. Part of ongoing discussions with a Key Customer looking for fast and efficient support both on and off site.

SGT 200 Epicyclic Gearbox

An Allen SGT200 Epicyclic Gearbox, fully refurbished and overhauled within our facility in Bedford, this machine will be held in stock to support one of our Key Customers and will ensure minimal downtime in the event of a catastrophic gear failure.

Here at TMS we work with our end user base to meet their spares and service requirements, no customer is ever the same, therefore we remain flexible to meet all challenges!

Input speed- 11053 Rpm

Output Speed -1500 Rpm

Rated Power-8580 Kw

Designed to -AGMA 421.06

Service Factor 1.3

ASG 32